In this system, it has been confirmed that the discharge reaction product is not a solid substance like lithium oxide (Li 2O), but lithium hydroxide (LiOH), which dissolves in the aqueous electrolyte, and so clogging of the pores does not occur at the carbon cathode. If the two sides are separated by a solid electrolyte which allows only lithium ions passing through, the two electrolytic solutions do not mix with each other while the charge-discharge reactions proceed smoothly.

This study is based on the idea of using an organic electrolyte only on the anode side, and using an aqueous electrolyte on the cathode side. This study was partly supported by Grants-in-Aid for Scientific Research program of JSPS. To overcome problems with conventional lithium-air batteries, AIST has been developing new lithium-air batteries that use an organic electrolyte and metallic lithium on the anode side, the air and an aqueous electrolyte on the cathode side, and a solid electrolyte LISICON as a partition wall to separate them. 1 Schematic diagram of a conventional lithium-air (oxygen) battery. Hydrogen gas, which is dangerous, is produced if moisture in the air reacts with metallic lithium.ĭischarging would be disturbed if the nitrogen gas in the air reacts with metallic lithium.įig. It blocks pores, and disturbs discharging. Problems with conventional lithium-air cells:Ī solid reaction product (Li 2O) accumulates at the cathode. Lithium-air batteries also have been aggressively developed to achieve even larger energy densities. Targeting high performance lithium-ion batteries, the Energy Technology Research Institute of AIST demonstrated that nano-structured electrode materials provide high rate performance of Lithium ion batteries (AIST press releases of Jan. Right: Comparison of cathode discharging capacity with that of conventional lithium ion battery.Ĭalculated based on mass of air electrode = (porous carbon + catalyst + binder) and mass of cathode of a lithium-ion battery = (active material + conduction assisting carbon + binder)

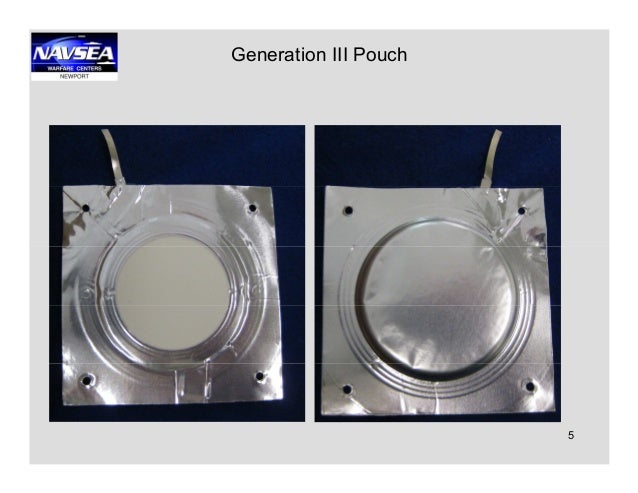

Left: Configuration of a newly developed lithium-air cell The result of the study will be presented at an Electrochemical Society of Japan meeting held in Kyoto on March 31, 2009. This is truly a new type of lithium fuel cell. It is easy to retrieve metallic lithium from the aqueous electrolyte, so that lithium can be reused.

#Lithium air battery overview driver#

At a filling station, the driver of a vehicle thus equipped could exchange the aqueous electrolyte for the air electrode and refill the metallic lithium for the anode in the form of cassettes, and then continue driving without waiting for batteries to be recharged. This technology holds great potential for automobile batteries. Continuous discharging of 50,000 mAh/g (per unit mass of the carbon, catalyst and binder) has been experimentally confirmed. At the cathode, the reaction product in the discharge process is water-soluble and no solid substances are produced. Only lithium ions pass through the solid electrolyte, and the battery reactions proceed smoothly. The two electrolytes are separated by a solid state electrolyte (lithium super-ion conductor glass film=LISICON) so that the two electrolytic solutions do not intermix. In this study, an organic electrolyte is used on the anode (metallic lithium) side and an aqueous electrolyte is used on the cathode (air) side. If the air electrode is fully clogged, O 2 from atmosphere cannot be reduced any more. However, one of serious problems with lithium-air batteries reported to date is that a solid reaction product (Li 2O or Li 2O 2), which is not soluble in organic electrolyte, clogs on the air electrode (=cathode) in the discharge process. Lithium-air batteries are attractive because they are theoretically advantageous in terms of their potential for future large-capacity batteries.

Lithium-ion batteries are widely used in mobile phones, computers and other electronic devices, however, their energy density is still insufficient for them to be used in electric vehicles.

Haoshen Zhou (Leader), the Energy Interface Technology Group, the Energy Technology Research Institute (Director: Yasuo Hasegawa) of the National Institute of Advanced Industrial Science and Technology (AIST) (President: Hiroyuki Yoshikawa) and Yonggang Wang (Japan Society for the Promotion of Science (JSPS) Postdoctoral Fellow) have developed a new-type lithium-air cell with large-capacity based on new structure.

0 kommentar(er)

0 kommentar(er)